A LEGACY OF

EXCELLENCE.

COMING TO

AMERICA.

Italian precision engineering is here.

The range of Schiavi America press brakes offers high quality solutions, able to meet the manufacturing demands of numerous sectors. Schiavi America assures extremely precise bending angles, that do not require further corrections by the operator, for the production of all shapes.

Combined with a powerful in-house software, the Schiavi America press brakes have been a reference for over sixty years for its user friendly format, reliability, precision and low-cost maintenance.

PRESS BRAKES

LINEAR

The LineAr is the top of the Schiavi range: a press brake that revolutionizes the world of bending by eliminating the canoe effect with an internationally patented solution that keeps the tool holder tables perfectly horizontal and parallel, ensuring an absolute linearity of the profile.

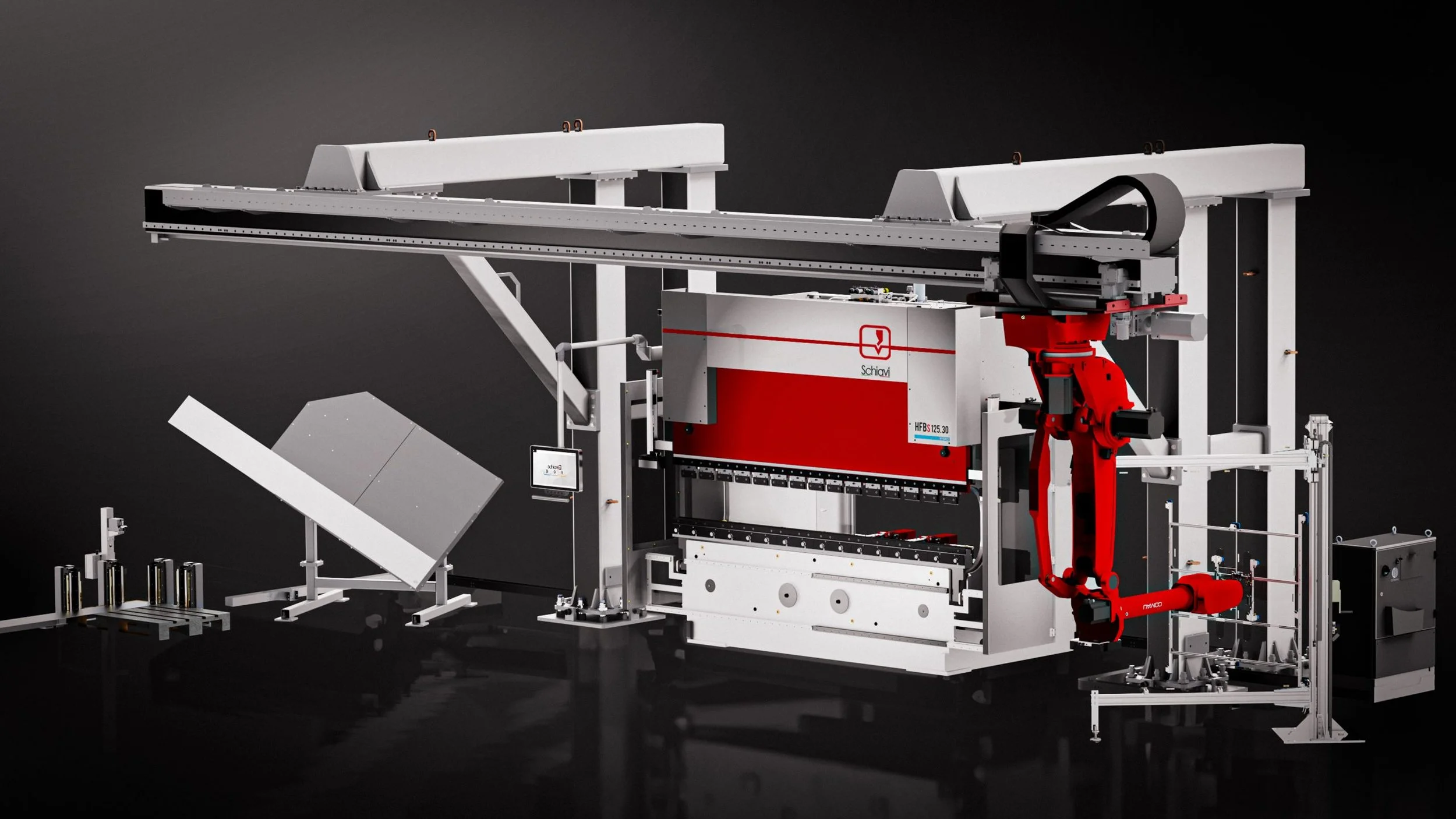

HFBs

The HFBs press brake is the perfect solution for customers who require impeccable bending accuracy and large-scale production.

The HFBs ensure high versatility and flexibility with excellent results in the production of different thickness sheet parts.

HFBx

Schiavi HFBx press brakes represent the most versatile model in automated bending processes.

The HFBx has been designed to facilitate the withdrawal and removal of complex profile parts and is particularly suitable for robotic solutions.

BSTs

The BSTs range guarantees safety and flexibility in a competitive package. The range has been designed for simple and fast bending but also offers the accuracy and constancy synonymous with the Schiavi name.

BENDING CELLS

A robotic bending cell is an advanced automated system that integrates a press brake with a 6- or 7-axis robot, designed to perform all standard bending operations, from picking flat parts and bending the workpiece to unloading the finished part.